Aug . 03, 2025 02:40 Back to list

Immunovital Fish Feed Factory | AI-Optimized Nutrition

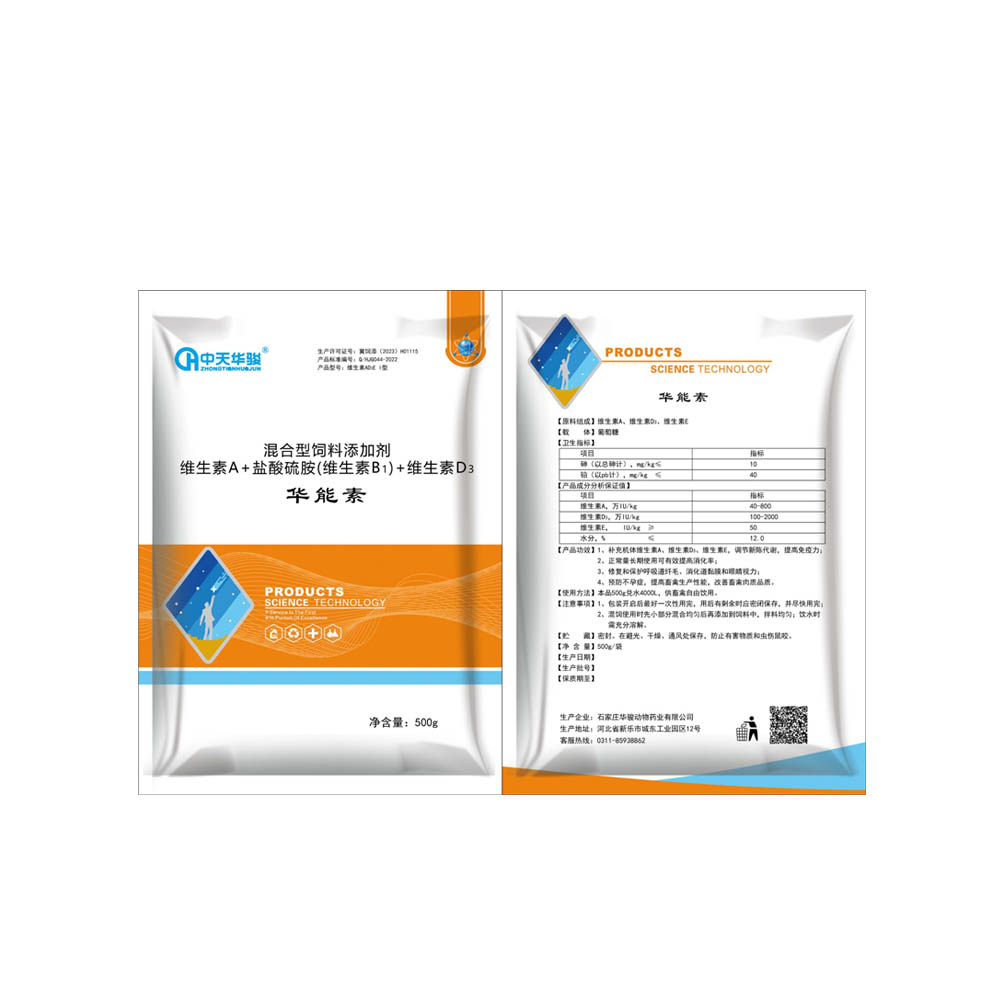

As the global demand for sustainable aquaculture grows, the necessity for high-quality, nutritious feed becomes paramount. This presents an expanding market for immunovital fish feed factories and vitamin additive manufacturers. In this in-depth guide, we explore the future of fish feed nutrition, focusing on cutting-edge technology, parameters, manufacturer comparison, and real-world application scenarios. Special focus is placed on our industry-leading product: Mixed Feed Additives with Vitamin. (product details)

Industry Overview and Trends (2024+)

- Global aquafeed market size: Expected CAGR of 6.8% from 2023-2028 (Markets&Markets, 2024).

- Shift towards functional feed: Rise of immunovital formulations to boost fish immunity and survival rates.

- Increasing regulation: Stringent quality/traceability standards—ISO 22000, GMP+, FDA, FAMI-QS.

- Key growth driver: Integration of vitamin C/E, enzyme blends, and probiotics in feed formulation.

- Industry trend: Customizable vitamins blends for species-specific health optimization.

What is an immunovital fish feed factory?

An immunovital fish feed factory specializes in manufacturing fish feed enhanced with immunostimulants, micro-nutrients, vitamins (especially vitamin C and E), and essential minerals. Their production processes emphasize ingredient homogeneity, bioavailability, and contamination control, resulting in feed that boosts fish resistance, growth performance, and feed conversion rate (FCR).

Manufacturing Process Breakdown: From Raw Input to Finished Product

(Soy protein, fish meal, vitamins)

(Uniformity control)

(Vitamin/Enzyme Mixing)

(Shape stabilization)

(ISO, FAMI-QS, HPLC)

(Bulk/Custom Packs)

Material & Technology Parameter Table of Leading immunovital fish feed factory

| Factory Name | Feed Types | Vitamin Integration Method | Process Cert. | Main Material | Typical Particle Size | Service Life / Stability |

|---|---|---|---|---|---|---|

| ZH Pharmatech (China) |

Pellets, Crumbles, Micro-feed | Microencapsulation with heat-protective coating (proprietary) | ISO 22000, GMP+, FDA, FAMI-QS | Marine protein, soybean, microcrystalline vitamin C, E | 0.3–2.0 mm | ≥96% potency/6 months |

| BIOVITA (EU) | Floating & Sinking Pellets | Vacuum coating (post-extrusion) | ISO 9001, HACCP | Fish meal, plant concentrates, vitamin premix | 0.5–2.5 mm | ≥93% potency/6 months |

| OceanFeed Intl. | Micro feed, Larval diets | Cold process blending | GMP+, FAMI-QS | Fish protein hydrolysate, vitamins | 0.1–1.2 mm | ≥92%/4 months |

Product Highlight: Mixed Feed Additives with Vitamin (ZH Pharmatech)

Applications: Aquaculture (tilapia, carp, catfish, shrimp), Livestock, Pet feeds

Key Constituents: Vitamin C (L-ascorbic acid), Vitamin E, B-group vitamins, carrier minerals, micro-nutrient blend

Manufacturing: Advanced microencapsulation + spray drying for maximum stability during pelleting and extrusion.

Technical Specification Table: Mixed Feed Additives with Vitamin

| Parameter | Specification | Test Method |

|---|---|---|

| Vitamin C Content | 12% min. / 120g/kg | HPLC (ISO 11085) |

| Vitamin E Content | 6% min. / 60g/kg | USP, AOAC 992.03 |

| Particle Size | 0.3–1 mm (D90) | Laser diffraction |

| Moisture | Oven drying (ISO 712) | |

| Loss on Drying | < 5% | AOAC 925.40 |

| Bioactivity Retention | >94% (6 months at 25°C) | Stability Test (ICH Q1A) |

| Heavy Metals | <10 ppm (Total) | ICP-MS |

| Bacterial Endotoxins | < 10 EU/g | LAL Test (USP 85) |

Comparison: Vitamin Additive Content in Key Products

immunovital fish feed factory: Technical Strengths & Advantages

- Advanced Encapsulation: Prevents vitamin breakdown during extrusion (heat-resistant up to 120°C), ensures >94% bioactivity.

- Nutrition Customization: Recipe tailoring for different fish species and growth phases (see immunovital fish feed manufacturer catalogs).

- Durability & Storage: Protective coatings provide ≥6 months bioactivity retention at 25℃/humidity 60%, outperforming generic vitamin c factories’ supplies.

- Testing & Auditing: Full batch traceability, in-line NIR testing, finished product HPLC/ICP-MS validation (meets ISO, AOAC, and USP standards).

- Corrosion & Pathogen Resistance: Key for aquaculture systems exposed to fluctuating pH, brackish water, and pathogen load.

- Regulatory Compliance: All ingredients meet global regulatory requirements: ISO 22000, GMP+, FDA, FAMI-QS.

- Eco-efficiency: Reduced waste output and energy-efficient extrusion pipelines.

Manufacturer Comparison: immunovital fish feed manufacturer vs. vitamin c factory

| Company | Core Product | Quality Standard | Customization | Application | Annual Capacity | Global Supply |

|---|---|---|---|---|---|---|

| ZH Pharmatech | Mixed Feed Additives with Vitamin | ISO 22000, FAMI-QS, FDA, GMP+ | High (species-specific blends) | Aquaculture/Livestock | 15,000 MT | 55 countries |

| BASF (Germany) | Purified Vitamin C powder | USP, AOAC | Low | Feed/food/pharma | 22,000 MT | Worldwide |

| Zhengzhou Vital | Vitamin C 99% granule | ISO 9001, FSSC 22000 | Moderate | Feed/food | 14,000 MT | Asia, Africa |

Custom Solution Roadmap: From Idea to Finished Immunovital Feed (with Vitamin Additives)

- Needs Assessment – Detailed survey of client’s livestock/fish species, water conditions, growth target (by immunovital fish feed supplier technical team).

- Formula Design – R&D proposes a species-specific vitamin/mineral/probiotic blend (e.g., vitamin C: 100–120mg/kg for carp fry, see vitamin c manufacturer data sheets).

- Pilot Run & Lab Analysis – Micro-batch produced with HPLC, NIR, microbiology panels for full validation.

- Scale-up Manufacturing – Full process control via ISO/FAMI-QS standards; continuous blending/extrusion with in-line sensors.

- Packaging & Shipping – Bulk (25kg, 500kg) or branded small packs, vacuum-sealed to prevent oxidation.

- Aftermarket Support – Application guides, yield tracking, and ongoing tech support via dedicated vitamin c supplier division.

Application Scenarios & Real-World Cases

Scenario 2: Shrimp aquaculture experiencing lower oxidative stress and disease outbreaks after transitioning to advanced vitamin C-supplemented feeds by a leading immunovital fish feed manufacturer.

Scenario 3: Recirculating Aquaculture System integrator in Norway achieved 11% lower mortality and reduced antibiotic use — documented in a comparative study (2023).

Customer Testimonials and Feedback

— Farm Manager, Shandong Dadi Aquaculture Group (2024)

FAQs: Professional FAQ

Q1: What is the primary material composition used in immunovital fish feed factory products?

Q2: What are typical particle sizes and why do they matter?

Q3: Which industry installation and quality standards does ZH Pharmatech comply with?

Q4: What is the recommended vitamin C dosage in feed for optimal fish immunity?

Q5: How does microencapsulation enhance vitamin stability?

Q6: What is your average order to delivery cycle time?

Q7: What is the product shelf life and batch traceability protocol?

After-sales Service, Warranty & Customer Support

- Warranty: Certified quality on all batches, ≥12 months shelf stability guarantee.

- 24/7 Technical Support: Live online and phone support with nutritionists and process engineers.

- Application Training: Free protocols for feed preparation, minimization of nutrient leaching, and storage best practices.

- Documented Batch Traceability: All products are QR-batch coded; regulatory verification available upon request.

- Return/Claim Policy: Full refund or replacement for batches not meeting specification upon third-party inspection report.

Why Choose ZH Pharmatech as Your immunovital fish feed supplier or Vitamin C Partner?

- 20+ years dedicated to vitamin additive R&D and feed formulation

- Supplying Top 10 global aquaculture enterprises; proven case studies

- ISO, FAMI-QS, and FDA-certified processes ensure food and feed safety

- In-house tech team for real-time customization and formula optimization

Fast Quotation & Sample Request

Email: info@zthjpharma.com

Typical response time: within 12 hours

MOQ: 200kg; Free sample (500g) for evaluation.

- ScienceDirect: Immunostimulants & Vitamin C in Aquaculture Feeds

- MDPI Animals Journal: Vitamin C/E Bioavailability Analysis in Fish

- International Feed Industry Federation: Global Feed Manufacturing Statistics

- Markets & Markets: Aqua Feed Market, 2024–2028

- The Fish Site: New Study on Feed Formulation in Tilapia

This is the last article

-

Immunovital Fish Feed Factory | AI-Optimized Nutrition

NewsAug.03,2025

-

Quality Bacillus Coagulans BC30 Factory - Expert Production

NewsAug.02,2025

-

China Salivation AI with GPT-4 Turbo Features

NewsAug.01,2025

-

Epic Sepsis Factories: AI-Driven Detection with GPT-4 Turbo

NewsJul.31,2025

-

Acute Salpingitis and Oophoritis AI Factory

NewsJul.31,2025

-

Premium China Bacillus Subtilis Supplier & Factory Solutions

NewsJul.30,2025