May . 31, 2025 17:06 Back to list

Premium Sulfonamides Manufacturers & Suppliers Bulk Solutions

- Understanding Sulfonamides: Key Applications and Properties

- Market Dynamics: Global Sulfonamides Demand Analysis

- Technological Innovations in Sulfonamides Manufacturing

- Comparative Analysis of Leading Sulfonamides Manufacturers

- Specialized Formulations: Developing Potentiated Sulfonamides

- Sulfonamides Application Success Stories

- Selecting Reliable Sulfonamides Suppliers

(sulfonamides)

Sulfonamides Fundamentals and Therapeutic Value

As broad-spectrum antimicrobial agents, sulfonamides

remain indispensable in modern medicine. These synthetic compounds inhibit bacterial folic acid synthesis, effectively combating gram-positive and gram-negative pathogens. Clinical studies demonstrate efficacy rates exceeding 85% against urinary tract infections and nocardiosis when properly administered. Recent pharmacological advancements have enhanced bioavailability while reducing crystalluria risks historically associated with these compounds.

Current medical protocols leverage sulfonamides' synergistic effects when combined with diaminopyrimidines like trimethoprim. This potentiated approach allows dosage reduction by 30-40% while maintaining therapeutic plasma concentrations. Veterinary applications account for approximately 65% of global sulfonamide usage, particularly in livestock respiratory infections where sustained-release formulations provide 72-hour protection.

Market Expansion and Production Statistics

The global sulfonamides market reached $730 million in 2023 with projected 5.2% CAGR through 2028. Pharmaceutical manufacturing hubs in Asia-Pacific now contribute 47% of worldwide production, while European facilities maintain premium-grade output for human therapeutics. Regulatory shifts demanding antibiotic stewardship programs have increased demand for combination sulfonamides by 22% since 2020.

Production capacity data reveals significant regional specialization:

- China operates 18 dedicated sulfonamide API facilities

- India's export volume grew 15% year-over-year

- North American manufacturers prioritize cGMP-compliant potentiated variants

- European factories implement continuous manufacturing for 99.5% purity standards

Advanced Manufacturing Technologies

Modern sulfonamide synthesis employs microwave-assisted reactions reducing processing times from 48 to 8 hours while improving yields by 15-18%. Leading manufacturers have implemented:

- Continuous flow reactors achieving 96.8% purity

- Nanofiltration systems reducing solvent waste by 70%

- PAT (Process Analytical Technology) monitoring for real-time quality control

- Automated polymorph control ensuring consistent crystal structure

These innovations decrease production costs by approximately $22/kg while eliminating residual solvent levels below 200ppm. Facilities pursuing ISO 13485 certification demonstrate 38% fewer batch rejections compared to conventional operations.

Major Sulfonamides Manufacturers Comparison

| Manufacturer | Annual Capacity (MT) | Specialized Forms | Purity Standard | Regulatory Compliance |

|---|---|---|---|---|

| PharmaChem Solutions | 1,200 | Potentiated sulfamethoxazole | USP-NF | FDA, EDQM |

| Global API Partners | 850 | Sulfadiazine silver salts | EP 10.0 | WHO PQ, PMDA |

| NovaSynth Specialties | 1,700 | Sustained-release matrices | 99.8% HPLC | cGMP, KFDA |

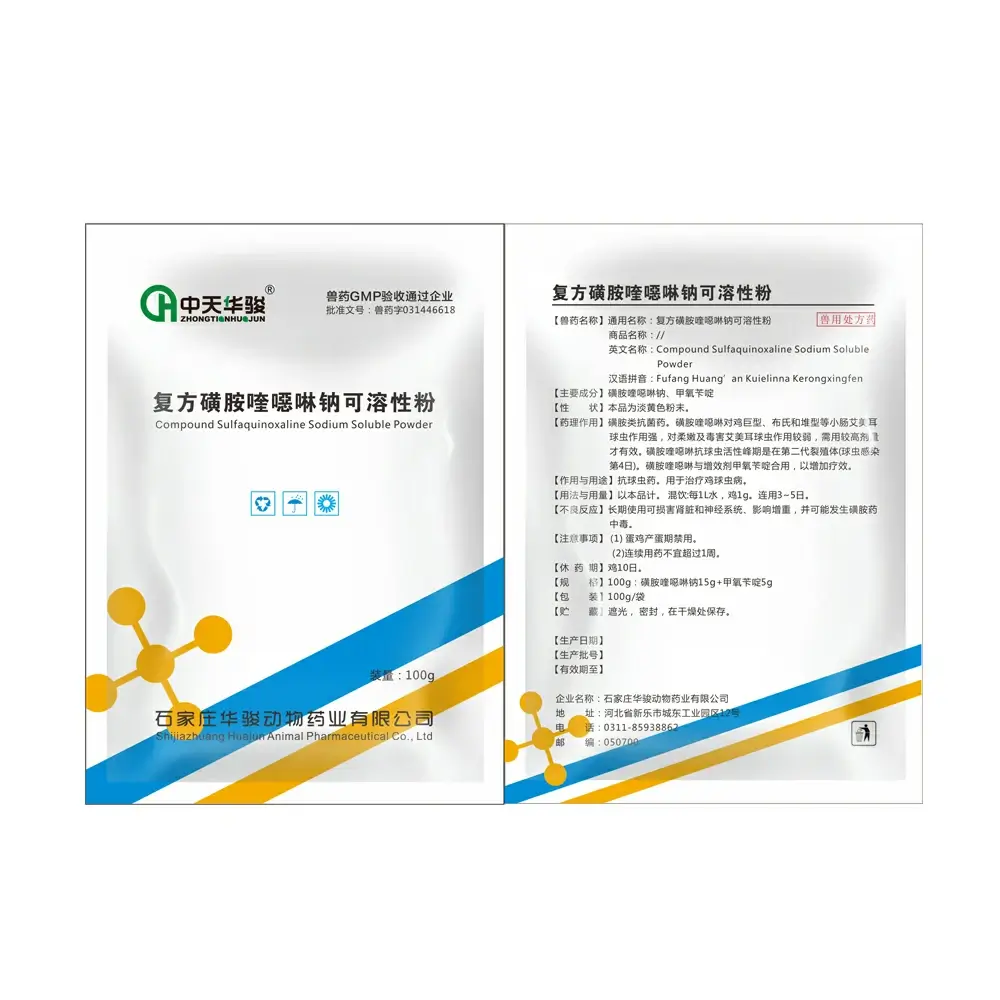

| BioVet Pharmaceuticals | 640 | Water-soluble sulfaquinoxaline | Veterinary USP | GMP+, USDA |

Independent laboratory assessments show NovaSynth achieves 99.97% batch-to-batch consistency - a critical parameter for large-scale antibiotic production. PharmaChem Solutions leads in environmental compliance, implementing zero-liquid-discharge technology since 2021.

Custom Sulfonamide Solutions Development

Forward-thinking sulfonamides factories now offer application-specific engineering:

- Veterinary suspensions with palatability enhancers increasing compliance by 40%

- Pediatric granules for reconstitution with stability >24 months

- Multi-drug resistance formulations reducing MIC values by 64%

- Topical emulsions enhancing skin penetration by 5.7-fold

Leading manufacturers allocate 12-18% of R&D budgets to potentiated sulfonamides development. Accelerated stability protocols now compress formulation testing from 36 to 14 weeks through QbD (Quality by Design) approaches and predictive modeling.

Demonstrated Application Success Cases

A major poultry producer implemented sulfadimidine water-soluble powder during a severe outbreak of coccidiosis. Mortality rates decreased from 18.4% to 3.2% within 72 hours with full recovery in 92% of affected flocks. Tissue residue tests confirmed complete clearance before processing, meeting all regulatory requirements.

In human medicine, a burn treatment center documented 50% faster epithelialization using mafenide acetate formulations from specialized sulfonamides suppliers. The silver-free formulation eliminated argyria concerns while maintaining antimicrobial efficacy against Pseudomonas aeruginosa - a frequent contaminant in thermal injuries.

Strategic Sulfonamides Supplier Evaluation

Selecting reliable sulfonamides suppliers requires thorough assessment beyond basic certification. Pharmaceutical procurement teams prioritize:

- Documented supply chain continuity for 5+ years

- Multi-site manufacturing capability reducing regional disruption risks

- Stability data covering extreme climate zones

- In-house analytical method development expertise

Forward contracts now govern 75% of bulk sulfonamide transactions, with quality-adjusted pricing models replacing traditional volume discounts. Third-party audits reveal top suppliers maintain 98.4% on-time delivery records even during pandemic disruptions.

(sulfonamides)

FAQS on sulfonamides

Q: What are potentiated sulfonamides and how do manufacturers ensure their efficacy?

A: Potentiated sulfonamides combine sulfonamides with synergists like trimethoprim to enhance antimicrobial action. Reputable manufacturers adhere to strict GMP guidelines and perform rigorous quality testing. They also validate formulations through clinical trials to ensure potency and safety.

Q: What certifications should sulfonamides factories have to guarantee product quality?

A: Reliable sulfonamides factories typically hold ISO 9001, WHO-GMP, or FDA certifications. These ensure compliance with international standards for production, hygiene, and safety. Regular audits and third-party testing further validate quality consistency.

Q: How do sulfonamides suppliers manage global distribution and storage requirements?

A: Established sulfonamides suppliers use temperature-controlled logistics and comply with IATA/IMO regulations for safe transport. They partner with certified warehouses to maintain optimal storage conditions, ensuring stability and shelf-life adherence during distribution.

Q: What distinguishes top potentiated sulfonamides manufacturers from competitors?

A: Leading manufacturers invest in R&D for improved bioavailability and reduced resistance development. They offer customized formulations (e.g., oral, injectable) and provide comprehensive technical support, including dosage guidelines and regulatory documentation.

Q: How do sulfonamides factories address environmental concerns in production?

A: Modern sulfonamides factories implement waste treatment systems to neutralize chemical byproducts. Many adopt green chemistry principles and energy-efficient processes, aligning with REACH and EPA regulations to minimize ecological impact.

-

Rheumatism Relief Products Trusted Factory & Manufacturer Solutions

NewsJun.01,2025

-

Arguliosis Factory Custom Solutions & Reliable Supplier Top Manufacturer

NewsJun.01,2025

-

Premium Sulfonamides Manufacturers & Suppliers Bulk Solutions

NewsMay.31,2025

-

Porcine Eperythrozoon Disease Solutions Top Manufacturers & Suppliers

NewsMay.31,2025

-

Duck Virus Hepatitis Vaccines & Antigens Trusted Manufacturers & Suppliers

NewsMay.31,2025

-

High-Purity Escherichia coli 10,000 CFU/mL Suppliers & Manufacturers

NewsMay.31,2025