Jul . 15, 2024 16:48 Back to list

Manufacturing of second generation cephalosporins in a pharmaceutical production facility

2nd generation cephalosporins, also known as second-generation cephalosporins, are a class of antibiotics that are used to treat a variety of bacterial infections. They are derived from cephalosporin C, a naturally occurring compound found in the fungus Acremonium. These antibiotics are commonly used to treat respiratory tract infections, urinary tract infections, skin infections, and infections of the bone and joint.

The production of 2nd generation cephalosporins is a complex and multi-step process that takes place in a specialized pharmaceutical factory. The first step in the production process is the cultivation of the fungus Acremonium, which produces cephalosporin C. This fungus is grown in large fermentation tanks, where it is allowed to multiply and produce the desired compound.

Once enough cephalosporin C has been produced, it is extracted from the fermentation tanks using a series of filtration and purification steps. The extracted cephalosporin C is then chemically modified to produce the desired 2nd generation cephalosporin antibiotic. This modification process involves the addition of various chemical groups to the cephalosporin C molecule, which alters its properties and enhances its effectiveness against bacterial infections.

2nd gen cephalosporins factory

After the chemical modification is complete, the 2nd generation cephalosporin antibiotic is purified and formulated into the final product

. This final product is usually in the form of a powder or a liquid, which is then packaged into vials or bottles for distribution to hospitals and pharmacies.Quality control is a critical aspect of the production process for 2nd generation cephalosporins. Each batch of antibiotic must undergo rigorous testing to ensure that it meets the required standards for purity, potency, and safety. This testing involves both chemical analysis and bioassays to determine the antibiotic's effectiveness against various bacterial strains.

Overall, the production of 2nd generation cephalosporins is a complex and highly regulated process that requires specialized facilities and equipment. The antibiotics produced in these factories play a crucial role in treating bacterial infections and saving lives. By adhering to strict quality control measures and following standardized production protocols, these factories ensure that patients receive safe and effective antibiotics to combat a range of infections.

-

Premium Avermectin Supplier in China | Custom Solutions Available

NewsJul.29,2025

-

China Bacillus Subtilis Supplier - Custom Factory Solutions

NewsJul.29,2025

-

China Salivation: Leading Custom Salivation Supplier & Factory Solutions

NewsJul.29,2025

-

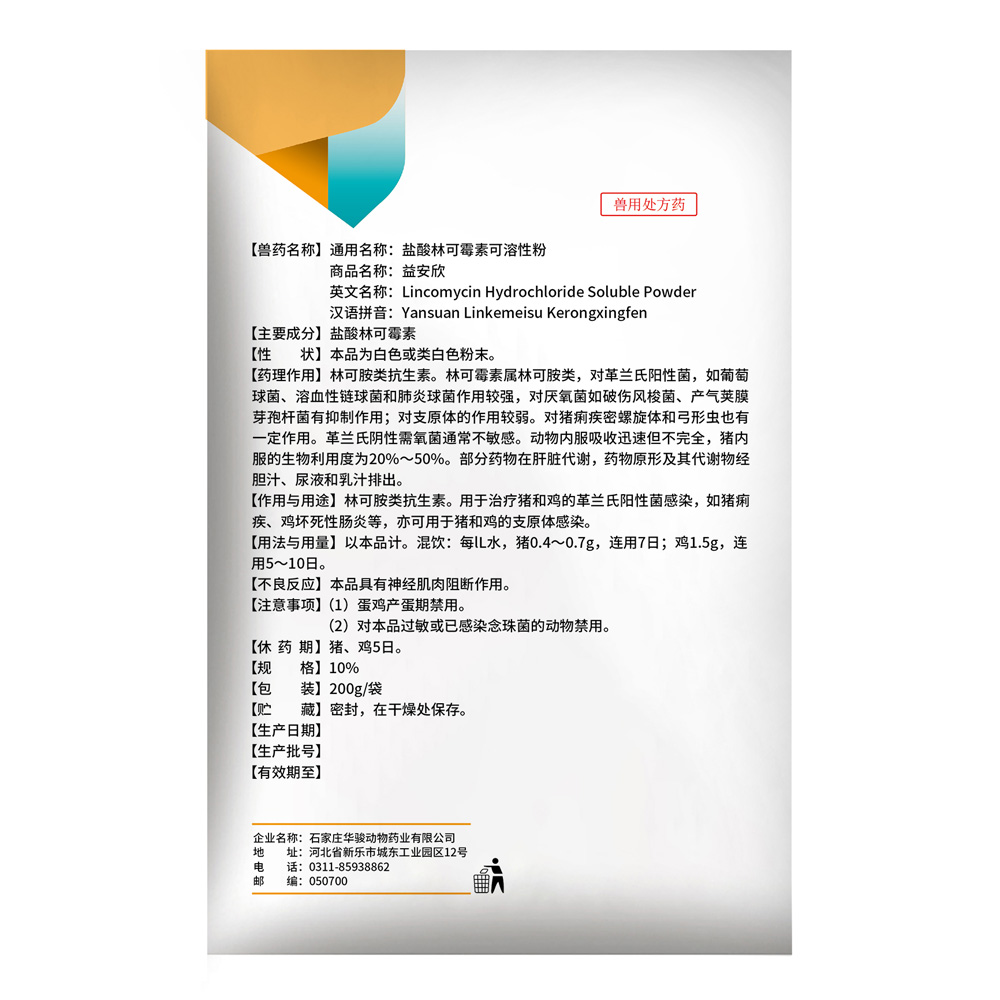

Leading Lincomycin Hydrochloride Manufacturer & Supplier with High Purity

NewsJul.29,2025

-

Bio-Enzyme Yogurt Growth Promoter Factory - Top Quality Manufacturer & Supplier

NewsJul.28,2025

-

Dexamethasone 10mg/ml Injection Solution Factory & Supplier Quality

NewsJul.27,2025