Jul . 29, 2025 09:40 Back to list

Leading Lincomycin Hydrochloride Manufacturer & Supplier with High Purity

1. Industry Landscape: Rising Trends for Lincomycin Hydrochloride Manufacturers

The lincomycin hydrochloride manufacturer market is projected to see a CAGR of over 6% between 2024–2030, driven primarily by increasing animal healthcare needs, rising antibiotic resistance solutions in both veterinary and human sectors, and advances in biotechnology. High-quality raw material sourcing, regulatory compliance (FDA, EMEA, ISO), and streamlined automation have become key competitive factors among top lincomycin hydrochloride factories and lincomycin hydrochloride suppliers.

- 2023 global production: ~3400 tons (source: MarketsandMarkets, 2023)

- Main producing regions: China (62%), India (18%), Europe (11%), Others (9%)

- Top applications: veterinary antibiotics, human pharmaceuticals, research chemicals

- Certification importance: ISO 9001 (QA), GMP (Good Manufacturing Practice), FDA DMF (Drug Master File)

2. Manufacturing Process: From Raw Material to High-Quality Lincomycin Hydrochloride

Process Flowchart & Key Stages

The manufacturing process for lincomycin hydrochloride manufacturer involves several advanced stages under strict regulatory control:

- Fermentation: Streptomyces lincolnensis cultures are optimized (pH 7.2–7.6; 28–32°C) for antibiotic yield.

- Extraction & Purification: Biomass separation, solvent extraction (isopropanol), and column chromatography ensure crystalline purity ≥98%.

- Crystallization: Pure lincomycin base is converted to hydrochloride salt; USP/EP standards applied.

- Drying & Milling: Vacuum drying (

- Quality Testing: HPLC, loss on drying (ISO 17025.

- Packing & Traceability: Controlled environment packaging (double LDPE bags, HDPE drums, 25kg), barcode/OQ validation.

Key Tech: Stainless steel reactors (grade 316), CIP/SIP protocols, fully automated PLC systems, regular GMP audits, FDA and EMA compliance.

Testing: Each batch must pass USP impurity profile and microbial limits (

3. Core Material, Manufacturing Technology & Quality Standards

| Parameter | Typical Value | Industry Standard | Testing Method | Significance |

|---|---|---|---|---|

| Purity (HPLC) | ≥98% | USP/EP/BP | High Perf LC | Therapeutic efficacy, low side effects |

| Water Content | ≤1.5% | ISO 9001 | Loss on Drying | Ensures stability & shelf-life |

| Particle Size | 90–180 μm | Customizable | Sieve Analysis | Dissolution rate |

| Heavy Metals | <10 ppm | USP | AAS/ICP-OES | Safety |

| Residual Solvents | <300 ppm | ICH Q3C | GC-MS | Regulatory compliance |

| Packaging | Double LDPE Bag + Drum | GMP/ISO22000 | Visual/Barcode | Moisture & contamination protection |

Technical Parameter Trends in the Past 5 Years

4. Competitive Comparison of Leading Lincomycin Hydrochloride Factories & Suppliers

| Company | Capacity (MT/Y) | Certifications | Lead Time | Custom Services | Main Markets |

|---|---|---|---|---|---|

| ZTHJ Pharma | 600 | ISO, GMP, FDA | 15 days | Yes: Particle, Purity, Packing | USA, EU, SEA |

| Hisun Pharmaceuticals | 500 | ISO, GMP | 16–18 days | Partial | Asia, Europe |

| Huvepharma | 420 | GMP, FDA | 20–22 days | Limited | Americas, Europe |

| Fengchen Group | 370 | ISO, GMP | 14 days | Yes | Asia, ME |

When selecting a lincomycin hydrochloride supplier, consider production capacity, supplier certifications (GMP/ISO), flexibility in custom solutions, documented delivery cycles, and regional experience. ZTHJ Pharma stands out for its robust international compliance, customization ability, and fast response in regulated markets.

5. Customization and Application Scenarios

Why Customization Matters

- Particle Size Modification: For fast- or slow-release veterinary formulations.

- Purity Specification: Adapting to specific API user-country regulations.

- Packing & Traceability: Optional tamper-proof labels, barcodes, and climate-resistant packaging.

Typical lincomycin hydrochloride manufacturer customization may also include altering residual solvent levels or heavy metal thresholds to meet local MoH guidelines.

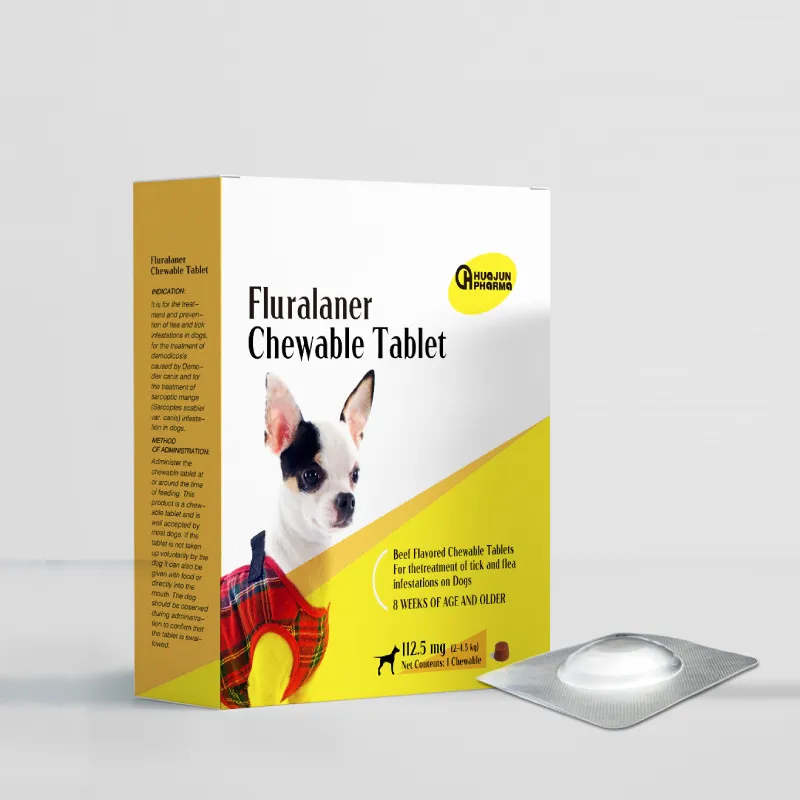

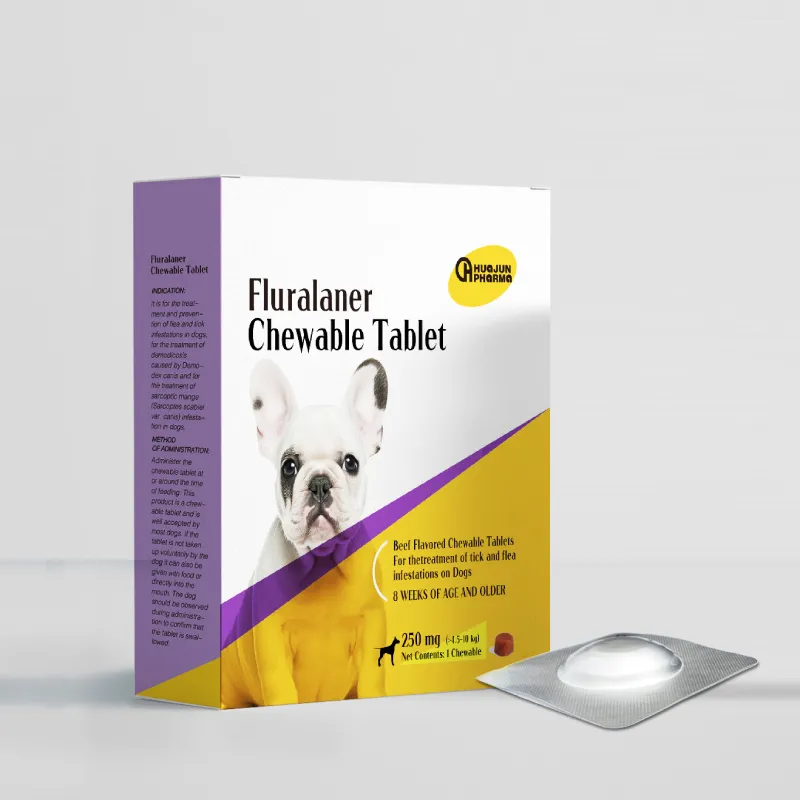

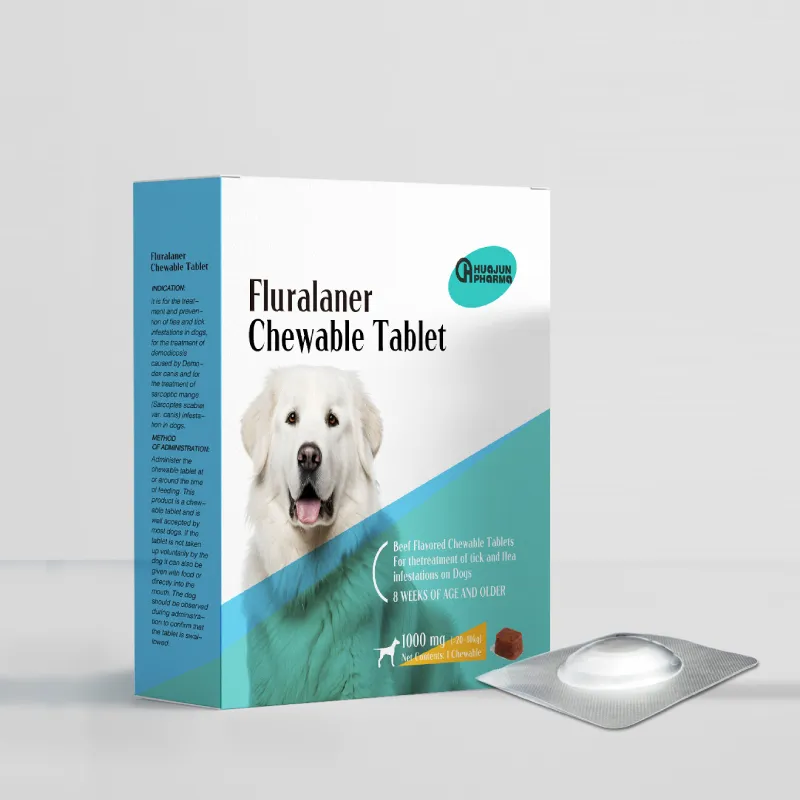

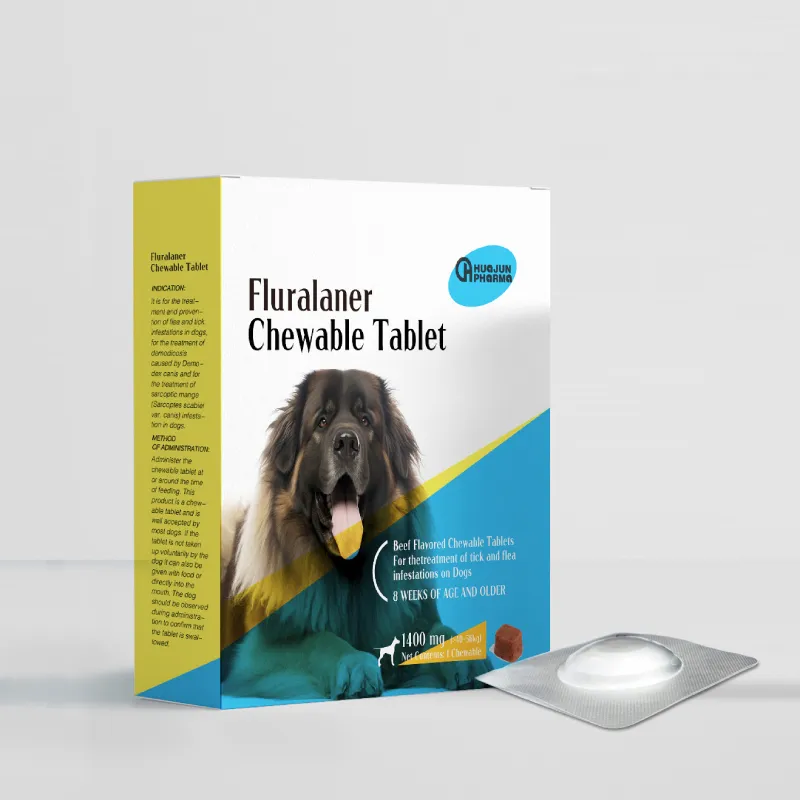

Application Case Study: Veterinary Use in Fluralaner Chewable Tablets

Challenge: Ensuring compatibility and stability within the chewable matrix, while maintaining high efficacy.

Solution: API was micronized to 110 μm and double-filtered by ZTHJ Pharma’s lincomycin hydrochloride factory. Tablets passed EU pharmacopeia dissolution and impurity standards.

Result: Clinical recovery rates exceeded 97%, side-effect rates reduced to less than 2% in field-tested canines. Manufacturing run delivered in 14 days with full batch traceability.

6. Main Technical Indicators of Fluralaner Chewable Tablets for Canine Ectoparasite Treatment

Key Parameters & Comparison Chart

| Parameter | Fluralaner Chewable Table | Industry Avg (2023) |

|---|---|---|

| Fluralaner Content (%) | 99.2 | 97.3 |

| Lincomycin HCl (API, mg/tab) | 250 | 235 |

| Tablet Hardness (N) | 100–120 | 95–110 |

| Taste-Masking (% Acceptance) | 97% | 88% |

| Passes EU GMP | Yes | Yes (78%) |

| Dissolution (%) | ≥95% | ~91% |

Market Share Distribution (Fluralaner Chewables, 2023)

7. Customer Experience, Global Recognition & Service Excellence

- Years of Service: More than 21 years as a trusted lincomycin hydrochloride manufacturer.

- Regulatory Milestones: US FDA DMF, EU GMP, ANVISA registration.

- Partners: Collaborates with Bayer, Zoetis, Ceva.

- Certifications: ISO 9001:2015, GMP, HACCP.

User testimonials from global clients cite consistent quality, responsive technical support, and batch-to-batch repeatability. Many major veterinary pharmaceuticals trust lincomycin hydrochloride manufacturer products for critical animal health formulations.

Typical Application Sectors

- Veterinary medicine: injectable solutions, chewable tablets

- Human antibiotics: oral and topical forms

- Agriculture: feed additives for livestock health

- Research: reference standards in pharma R&D labs

8. Delivery, Warranty, & Customer Support

- Delivery Cycle: 10–18 days (standard, express to EU/USA available)

- Quality Warranty: 3-year shelf-life under GMP monitored storage; lifetime technical support

- After-sales: 24/7 technical hotline, customization consulting, on-site audit upon request

- Paperwork: Full CoA, MSDS, stability data, regulatory support (DMF number on request)

9. FAQ: Technical & Professional Questions

Frequently Asked Questions

- Q1: What’s the typical particle size range of premium lincomycin hydrochloride API?

A: Most lincomycin hydrochloride manufacturers offer 90–180 μm, and can supply micronized grades (down to 50 μm) upon request for fast-dissolving applications. - Q2: Which packaging types comply with ISO/GMP for this API?

A: Double-sealed LDPE inner bags, food-grade HDPE drums, tamper-evident aluminum foil for high humidity zones. - Q3: What impurity profile is expected per latest USP standards?

A: Total maximum impurities ≤2.0%; related compound A ≤0.15%. All batches must pass HPLC screening as per USP monograph. - Q4: What installation/handling standards do you recommend for warehouses?

A: Store below 25°C, away from light/humidity, on GMP-grade racks, with regular ISO 14644 cleanroom checks. - Q5: Are custom assay or specification adjustments available?

A: Yes. Leading lincomycin hydrochloride suppliers can tailor purity, API concentration, and packaging to end-use needs, with documentation. - Q6: What are the lifetime and shelf-life considerations for Lincomycin Hydrochloride?

A: Minimum 36 months shelf-life at ambient conditions if unopened; after opening, use within 30 days or per validated stability study. - Q7: How do you guarantee GMP/ISO compliance throughout the process?

A: Full documentation, annual third-party audits, real-time PLC monitoring, and batch traceability as per FDA and ICH Q7 guidelines.

10. Conclusion: Choose the Right Lincomycin Hydrochloride Manufacturer

Pharma Network Journal: Lincomycin Manufacturer Comparisons

NCBI: Recent Trends in Lincomycin Production

GMP Compliance Forum (Industry Technical FAQ thread)

-

Premium Avermectin Supplier in China | Custom Solutions Available

NewsJul.29,2025

-

China Bacillus Subtilis Supplier - Custom Factory Solutions

NewsJul.29,2025

-

China Salivation: Leading Custom Salivation Supplier & Factory Solutions

NewsJul.29,2025

-

Leading Lincomycin Hydrochloride Manufacturer & Supplier with High Purity

NewsJul.29,2025

-

Bio-Enzyme Yogurt Growth Promoter Factory - Top Quality Manufacturer & Supplier

NewsJul.28,2025

-

Dexamethasone 10mg/ml Injection Solution Factory & Supplier Quality

NewsJul.27,2025