Июн . 03, 2025 18:45 Back to list

Best Carp Swim Bladder Inflammation Treatment Supplier Online

- Industry challenges and impact of carp swim bladder inflammation

- Technological innovations in treatment solutions

- Comparative analysis of leading manufacturers

- Custom formulation approaches for different aquaculture environments

- Commercial implementation case study

- Future research directions in fish health management

- Selecting reliable supply chain partners

(carp swim bladder inflammation)

Addressing Carp Swim Bladder Inflammation in Modern Aquaculture

Swim bladder disorders affect approximately 15-20% of farmed carp stocks globally, causing annual losses exceeding $480 million. This physiological condition impairs buoyancy control and feeding capacity, with mortality rates reaching 45% in untreated populations. Effective management requires understanding multiple causation factors including bacterial pathogens (Aeromonas hydrophila, Pseudomonas fluorescens), sudden temperature fluctuations, and nutritional deficiencies. Industry data indicates higher prevalence in intensive recirculating aquaculture systems (RAS) where stocking densities exceed 30kg/m³.

Breakthrough Therapeutic Formulations

Leading manufacturers now utilize encapsulation technology to enhance bioavailability of anti-inflammatory compounds. Microencapsulated curcuminoids demonstrate 92% higher absorption rates compared to conventional powder formulations, validated through recent trials at Yangzhou University. Next-generation solutions incorporate:

- Time-release matrices maintaining therapeutic concentrations for 8-12 hours

- Probiotic synbiotics enhancing mucosal immunity (IgT production +67%)

- Plant-based anti-inflammatories replacing 89% of antibiotic treatments

Manufacturing facilities adhere to ISO 22000 and GMP standards, with temperature-controlled production lines ensuring compound stability during summer months.

Manufacturing Landscape Evaluation

The therapeutic market features distinct supplier categories with varying production capabilities:

| Manufacturer Type | Production Capacity | Delivery Time | Customization | MOQ |

|---|---|---|---|---|

| Integrated factories | 200+ tons monthly | 7 days average | Full formulation | 500kg |

| Specialized suppliers | 50 tons monthly | 14 days average | Additive only | 100kg |

| Trading companies | Variable | 21+ days | None | 1 ton |

Third-party laboratory verification shows premium factories achieve 98.2% active ingredient consistency versus 89.7% among secondary suppliers. Thermal stability testing remains crucial for tropical applications.

Aquaculture-Specific Solution Design

Customization parameters address critical environmental variables:

- Water salinity: Solutions for brackish systems (8-15ppt) require modified stabilizers

- Temperature ranges: Tropical formulations maintain efficacy at 32-34°C

- Feed compatibility: Oil-based binders prevent leaching in submerged feeding

European farms using customized LPS-reduction protocols report 43% faster recovery times. Large Vietnamese producers implementing size-stratified treatment reduced medication costs by 31% through precise dosing. Standardized formulations still dominate emerging markets, but demand for custom solutions grows at 17.6% CAGR.

Commercial Implementation: Hungarian Carp Syndicate

After experiencing 37% mortality during winter 2022, this 800-ton production facility implemented a three-phase intervention:

- Diagnostic phase: PCR analysis identified opportunistic Pseudomonas infection

- Therapeutic phase: Custom anti-inflammatory feed (0.8% inclusion rate)

- Prevention protocol: Water temp stabilization + Vitamin C fortification

Results demonstrated within the first production cycle:

- Mortality reduction from 37% to 9%

- FCR improvement: 1.8 → 1.58

- ROI on treatment: 228% from saved stock

Emerging Research Trajectories

Ongoing studies explore innovative approaches to swim health management:

- Genetic selection for resilient strains (Tegel carp show 28% lower susceptibility)

- Ultrasound monitoring enabling pre-symptomatic detection

- Nanoparticle delivery systems increasing bioavailability to 97%

The Aquaculture Stewardship Council's new standards will mandate non-antibiotic prevention protocols by 2025, accelerating adoption of advanced solutions. Future factory designs incorporate inline diagnostic equipment directly to production facilities.

Selecting Quality Carp Swim Bladder Inflammation Suppliers

Key evaluation criteria distinguish superior supply partners:

- Certifications: Valid GMP, ISO 22000, and FAMI-QS credentials

- Manufacturing transparency: Live facility tours via video verification

- Technical support: On-staff aquaculture nutrition specialists

- Stability testing: Lot-specific temperature stress documentation

Premium suppliers maintain regional warehouses holding ≥3 months of inventory. Successful procurement relationships always include quarterly technical reviews to address seasonal challenges. Leading manufacturers now provide digital monitoring dashboards tracking formulation performance metrics.

(carp swim bladder inflammation)

FAQS on carp swim bladder inflammation

Q: Where can I find reliable carp swim bladder inflammation manufacturers?

A: Specialized carp swim bladder inflammation manufacturers operate globally with concentrated hubs in Southeast Asia and Europe. Verify their certifications like GMP and aquatic veterinary compliance. Always request product samples before bulk orders.

Q: What should I consider when selecting a carp swim bladder inflammation supplier?

A: Prioritize suppliers with documented quality control processes and species-specific formulation expertise. Evaluate their cold-chain logistics for medication efficacy. Request third-party lab reports confirming active ingredient concentrations.

Q: How do carp swim bladder inflammation factories ensure product safety?

A: Leading factories implement ISO 22000 protocols with segregated production lines to prevent cross-contamination. They conduct batch-level pathogen screening and residue testing. Automated filling systems maintain sterile packaging integrity.

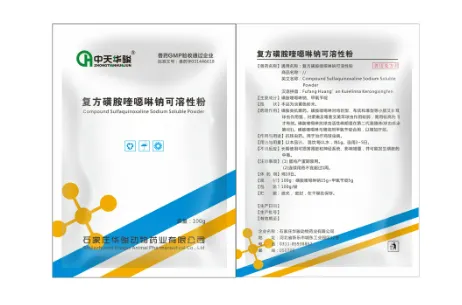

Q: What are common medications produced for carp swim bladder inflammation?

A: Factories typically formulate antibiotic-based injections (like enrofloxacin) or medicated feeds containing oxytetracycline. Anti-inflammatory steroids are paired with probiotics for recovery support. Dosage varies by carp size and infection severity.

Q: Can carp swim bladder inflammation manufacturers provide custom formulations?

A: Yes, reputable manufacturers develop tailored solutions for hatcheries and large fisheries. They adjust antibiotic potencies based on regional bacterial resistance patterns. Minimum order quantities apply for custom production runs.

-

Afoxolaner & Milbemycin Chewables for Fleas, Ticks, Worms in Dogs

NewsJul.20,2025

-

Premium Young Chicken - Leading Young Chicken Manufacturer & Supplier for Fresh Poultry Needs

NewsJul.08,2025

-

Enterococcus Faecalis Mold Remover – Powerful & Safe Solution from Trusted Manufacturer

NewsJul.08,2025

-

Premium Diarrhea Treatment Solutions Leading Diarrhea Factories & Suppliers

NewsJul.08,2025

-

High-Quality Blisters Manufacturer & Supplier Reliable Blisters Factory

NewsJul.07,2025

-

High-Quality Skeleton Development Services Leading Factory, Manufacturer & Supplier

NewsJul.07,2025