दिसम्बर . 03, 2024 17:13 Back to list

Salmonella Treatment Approaches in Food Processing and Manufacturing Industry

Salmonella Treatment in Food Processing Factories Best Practices and Innovations

Salmonella, a genus of bacteria that is often found in contaminated food, presents a significant public health challenge. It is one of the leading causes of foodborne illnesses globally, resulting in severe gastrointestinal distress and, in some cases, severe complications that can lead to hospitalization. This issue is particularly pressing for food processing factories, where the risk of contamination can span large-scale production lines. In tackling the threat of Salmonella, factory protocols and innovative treatment strategies are crucial.

Understanding Salmonella

Salmonella consists of a group of bacteria that can live in the intestines of many animals, particularly poultry and cattle. Humans typically contract Salmonella through the consumption of contaminated food products such as eggs, poultry, and unpasteurized dairy products. Symptoms of Salmonella infection may include diarrhea, fever, abdominal cramps, and vomiting, making prevention and control paramount for food manufacturers.

The Importance of Hygiene and Sanitation

One of the foundational practices in Salmonella treatment is rigorous hygiene and sanitation protocols within food processing factories. Maintaining a clean environment is critical to preventing contamination. Regular cleaning and sanitizing of equipment, surfaces, and processing areas helps to eliminate bacteria. Factory staff should be trained on proper handwashing techniques and personal hygiene standards to minimize the risk of foodborne pathogens being introduced into the processing environment.

Testing and Monitoring

Routine testing for Salmonella contamination is essential. Factories often implement frequent environmental monitoring programs, which involve routine sampling of surfaces, equipment, and raw materials. These samples are then tested for the presence of Salmonella. If contamination is detected, a thorough investigation is needed to determine the source and rectify the issue. This proactive approach not only ensures product safety but also helps in maintaining the factory's safety reputation.

Temperature Control

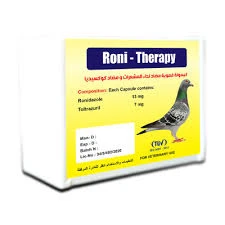

salmonella tratamiento factories

One effective method for controlling Salmonella in food products is through proper temperature control during processing and storage. Salmonella is sensitive to heat; therefore, cooking foods to the appropriate internal temperatures can kill the bacteria. Food processing facilities must ensure that cooking equipment is calibrated correctly, and temperature monitoring systems are in place to ensure food products are cooked adequately.

Conversely, cold storage units must maintain low temperatures to slow bacterial growth. Regularly checking and recording temperatures in meat lockers and refrigeration units can prevent the growth of Salmonella and other pathogens.

Innovative Technologies

As technology evolves, so do the methods for detecting and treating Salmonella. One of the most significant innovations in recent years is the development of rapid testing methods. These techniques allow for faster detection of pathogens, reducing response time when contamination is suspected.

Moreover, advances in food processing technologies such as high-pressure processing (HPP) and pulsed electric field (PEF) processing are emerging as effective ways to reduce or eliminate Salmonella in food products. These methods can effectively pasteurize foods without the need for extensive heat treatments, preserving the quality and taste of the product.

Employee Training and Awareness

A well-trained workforce is a key component in the fight against Salmonella. Workers must be educated on food safety practices, how to identify potential sources of contamination, and the importance of adhering to hygiene standards. Regular training sessions, updates on best practices, and ongoing education can keep employees informed and vigilant.

Conclusion

Salmonella poses a serious risk to public health, especially in food processing factories where the potential for widespread contamination exists. Implementing stringent hygiene protocols, regular testing, temperature control, and leveraging innovative technologies are vital strategies in the treatment and prevention of Salmonella. Moreover, ongoing employee training and awareness can foster a culture of food safety that significantly reduces the risks associated with this dangerous pathogen. By committing to these best practices, food processing factories can not only protect consumers but also enhance their operational integrity in the face of potential threats.

-

Top Hemoglobinuria Manufacturer & Supplier Reliable Hemoglobinuria Factory Solutions

NewsJun.24,2025

-

Premium Honeysuckle Products - Leading Honeysuckle Manufacturer & Supplier Factory

NewsJun.10,2025

-

Pulmonary Edema Solutions from Leading Manufacturer & Supplier Reliable Factory Price

NewsJun.10,2025

-

Red Eyes - Leading Red Eyes Manufacturer & Supplier, Premium Quality Factory Price

NewsJun.10,2025

-

Broiler Ascites Syndrome Solutions Top Manufacturers

NewsJun.10,2025

-

Premium Amoxicillin Suppliers Reliable Biomox Mexican Factories

NewsJun.10,2025