דצמ . 25, 2024 22:26 Back to list

norfloxacin ciprofloxacin factories

The Role and Impact of Norfloxacin and Ciprofloxacin Factories in the Pharmaceutical Industry

In today’s fast-paced pharmaceutical industry, the production of antibiotics plays a critical role in combating bacterial infections. Two significant members of the fluoroquinolone family are Norfloxacin and Ciprofloxacin, both of which are manufactured in various factories across the globe. Understanding the importance of these drugs, the manufacturing processes, and their implications on health care is paramount in recognizing their place in modern medicine.

The Importance of Norfloxacin and Ciprofloxacin

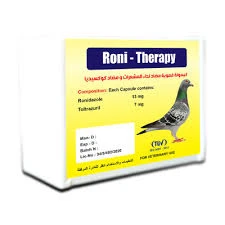

Norfloxacin and Ciprofloxacin are synthetic antibiotics that have been treated as cornerstones in the fight against bacterial infections. Norfloxacin, developed in the early 1980s, is mainly used to treat urinary tract infections and infectious diarrhea. On the other hand, Ciprofloxacin, which is a broader-spectrum antibiotic, is effective against a variety of gram-negative and some gram-positive bacteria. It is widely used for respiratory infections, skin infections, and even in some cases of anthrax exposure.

The growing prevalence of antibiotic resistance has underscored the necessity of these antibiotics. Their ability to inhibit bacterial DNA gyrase and topoisomerase IV makes them effective against a diverse range of pathogens. However, the rise of resistance necessitates a vigilant approach to their production and use, emphasizing the need for robust manufacturing standards and practices.

Manufacturing Processes in Factories

The factories producing Norfloxacin and Ciprofloxacin must adhere to stringent quality control measures to ensure that the end products are safe, effective, and free from contamination. The manufacturing process typically involves several key steps

1. Synthesis of Active Pharmaceutical Ingredients (APIs) This phase involves complex chemical reactions to create the active ingredients. The specific synthesis pathways depend on the compound being produced. For example, the synthesis of Ciprofloxacin requires a series of reactions involving piperazine and a fluoroquinolone intermediate.

2. Purification and Quality Control After synthesis, the active ingredients must be purified to remove any impurities. Various techniques such as crystallization and chromatography are utilized. Quality control tests are then performed to ensure that the products meet regulatory standards.

norfloxacin ciprofloxacin factories

3. Formulation The purified APIs are mixed with excipients to create the final pharmaceutical form, whether it be tablets, capsules, or injectable forms. This process must ensure uniformity in dosage and stability of the medication.

4. Packaging and Distribution Finally, the products are packaged in compliance with regulatory requirements. Proper labeling and storage conditions are critical to maintaining the efficacy of the antibiotics during transportation to healthcare providers and pharmacies.

Economic and Environmental Considerations

Factories producing Norfloxacin and Ciprofloxacin also play a crucial role in the economy. They not only provide employment opportunities but also contribute to local and national revenue. However, the production of pharmaceuticals is not without its challenges. The manufacturing process has environmental implications, particularly in the management of chemical waste. Many pharmaceutical factories are working to adopt greener practices to minimize their environmental footprint, including waste reduction techniques and energy-efficient processes.

Future Prospects

The future for Norfloxacin and Ciprofloxacin factories is likely to be shaped by advancements in technology and increasing globalization in the pharmaceutical industry. Artificial intelligence and machine learning are revolutionizing the way drugs are developed, potentially leading to faster and more efficient production methods. Furthermore, as antibiotic resistance continues to rise, there exists a pressing need for research into novel antibiotic compounds while maintaining production standards for existing medications.

Conclusion

In summary, the factories that produce Norfloxacin and Ciprofloxacin are essential to the healthcare landscape, providing tools to combat bacterial infections effectively. They face both opportunities and challenges, from innovation in manufacturing practices to the ethical need for sustainable operations. As we move forward, it is crucial to support these factories in maintaining high standards of quality and safety, ensuring that they can meet the demand for effective antibiotics in a responsible manner. The fight against bacterial infections hinges on the success of these facilities, underscoring their important role in public health and the pharmaceutical industry.

-

Immunovital Fish Feed Factory | AI-Optimized Nutrition

NewsAug.03,2025

-

Quality Bacillus Coagulans BC30 Factory - Expert Production

NewsAug.02,2025

-

China Salivation AI with GPT-4 Turbo Features

NewsAug.01,2025

-

Epic Sepsis Factories: AI-Driven Detection with GPT-4 Turbo

NewsJul.31,2025

-

Acute Salpingitis and Oophoritis AI Factory

NewsJul.31,2025

-

Premium China Bacillus Subtilis Supplier & Factory Solutions

NewsJul.30,2025