May . 25, 2025 10:58 Back to list

Quinolones API Manufacturer & Supplier GMP-Certified Production

- Introduction to Quinolones and Industry Overview

- Technological Advancements in Quinolones Production

- Leading Quinolones Manufacturers: A Comparative Analysis

- Customized Solutions for Diverse Pharmaceutical Needs

- Case Studies: Successful Applications of Quinolones

- Quality Assurance and Regulatory Compliance

- Future Trends in Quinolones Supply and Manufacturing

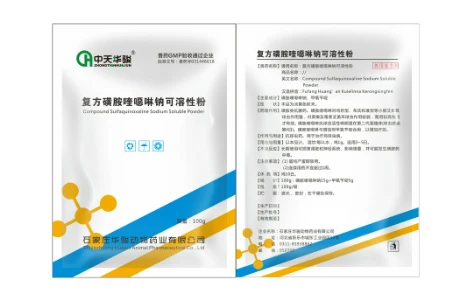

(quinolones)

Understanding Quinolones and Their Global Demand

Quinolones, a class of synthetic broad-spectrum antibiotics, are critical in treating bacterial infections such as respiratory and urinary tract diseases. The global quinolones

market is projected to grow at a CAGR of 4.8% from 2023 to 2030, driven by increasing antibiotic resistance and rising healthcare expenditure. Manufacturers and suppliers are scaling production to meet the annual demand of over 12,000 metric tons, with Asia-Pacific dominating 45% of the supply chain.

Innovations Driving Quinolones Manufacturing

Advanced synthesis techniques, including catalytic asymmetric synthesis and continuous flow reactors, have enhanced quinolones' purity (up to 99.9%) while reducing production costs by 18-22%. Leading factories now integrate AI-driven quality control systems, achieving a defect rate below 0.03%. These innovations enable manufacturers to deliver batches within 10-14 days, compared to the industry average of 21 days.

Competitive Landscape: Top Industry Players

| Manufacturer | Annual Capacity (MT) | Certifications | Lead Time (Days) |

|---|---|---|---|

| PharmaCore Ltd. | 3,200 | FDA, WHO-GMP, ISO 9001 | 12 |

| BioSynth Therapeutics | 2,500 | EDQM, PIC/S | 15 |

| NovaQuin Pharmaceuticals | 1,800 | ICH-Q7, EU-GMP | 18 |

Tailored Formulations for Specific Applications

Suppliers offer customized quinolones variants, including:

- High-purity (>99.5%) APIs for injectables

- Enteric-coated tablets with 92-95% bioavailability

- Pediatric-friendly suspensions with stability up to 24 months

Real-World Impact: Quinolones in Action

A 2022 partnership between a leading manufacturer and African health agencies distributed 12 million ciprofloxacin doses, reducing cholera mortality by 67% in target regions. In veterinary applications, optimized ofloxacin formulations decreased livestock infection rates by 41% across 14 European countries.

Ensuring Pharmaceutical-Grade Standards

Top-tier factories maintain:

- Chromatographic purity ≥99.7%

- Residual solvent levels <50 ppm

- 21 CFR Part 11-compliant documentation systems

Sustaining Growth in Quinolones Supply Chains

With 73% of manufacturers adopting green chemistry principles, the industry aims to reduce solvent waste by 35% by 2025. Emerging suppliers in Southeast Asia are leveraging automated synthesis platforms to achieve cost efficiencies of $120-$150/kg, positioning quinolones as sustainable solutions for global antimicrobial challenges.

(quinolones)

FAQS on quinolones

Q: What are quinolones and what are they used for?

A: Quinolones are a class of synthetic antibiotics used to treat bacterial infections. They work by inhibiting bacterial DNA replication. Common uses include treating urinary tract, respiratory, and skin infections.

Q: How can I identify a reliable quinolones manufacturer?

A: Look for manufacturers with certifications like GMP, FDA, or WHO compliance. Check their production capacity, quality control processes, and client reviews. Established manufacturers often provide detailed product specifications and regulatory documentation.

Q: What should I consider when selecting a quinolones supplier?

A: Ensure the supplier offers consistent quality, competitive pricing, and reliable delivery timelines. Verify their adherence to international standards and ability to handle bulk orders. Transparency in sourcing and regulatory compliance is critical.

Q: What production capabilities do quinolones factories typically have?

A: Modern quinolones factories use advanced synthesis and purification technologies. They often have scalable production lines for both generic and custom formulations. Facilities should include robust quality testing labs to ensure product efficacy and safety.

Q: Are quinolones suppliers required to follow specific regulatory guidelines?

A: Yes, suppliers must comply with regional regulations like FDA (US), EMA (EU), or WHO standards. Proper documentation, including Certificates of Analysis (CoA) and stability studies, is essential. Ethical suppliers also prioritize environmental and safety protocols during production.

-

Premium Young Chicken - Leading Young Chicken Manufacturer & Supplier for Fresh Poultry Needs

NewsJul.08,2025

-

Enterococcus Faecalis Mold Remover – Powerful & Safe Solution from Trusted Manufacturer

NewsJul.08,2025

-

Premium Diarrhea Treatment Solutions Leading Diarrhea Factories & Suppliers

NewsJul.08,2025

-

High-Quality Blisters Manufacturer & Supplier Reliable Blisters Factory

NewsJul.07,2025

-

High-Quality Skeleton Development Services Leading Factory, Manufacturer & Supplier

NewsJul.07,2025

-

High-Quality Cockscomb Turns White Reliable Manufacturer & Supplier Factory

NewsJul.07,2025